Geotextiles

What are Geotextiles?

Geotextiles are specialized fabrics employed in a wide range of construction projects. They offer an effective and cost-saving solution for ground reinforcement, enhancing the stability and longevity of infrastructure. Made from virgin polyester (PE) and polypropylene (PP) resins, geotextiles come in three main types: woven, non-woven and composite.

Types of Geotextiles:

-

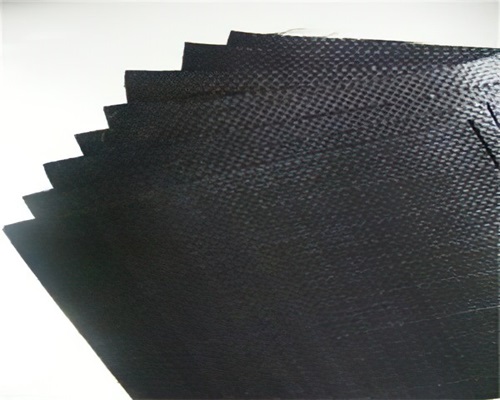

Woven Geotextiles: Composed of interlaced plastic fibers in a perpendicular pattern, resulting in a strong and durable bond. These textiles possess high tensile strength, ranging from several tens of kN/m to several hundred kN/m. Their exceptional load-bearing capacity makes them ideal for reinforcing ground treatment applications where required. Popular options include GET geotextiles and imported products from Korea and China. Common product codes include PP25, PP50, GET 5, GET 10, GET 20, and GET 200.

-

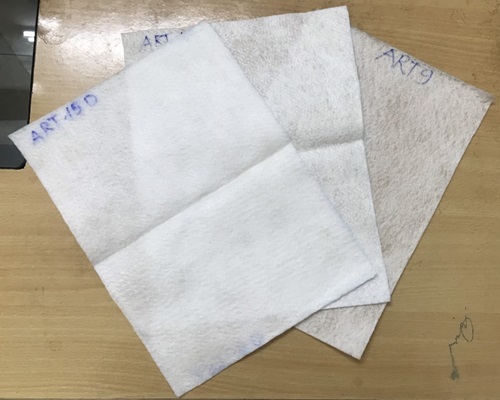

Non-Woven Geotextiles: Feature randomly interlaced plastic fibers without a specific orientation. The fibers are bonded using chemical (adhesive), thermal (heat), or mechanical (needle punching) methods. Non-woven geotextiles are commonly utilized in soil erosion control and ground improvement applications. The two most popular types in Vietnam are ART and TS geotextiles. Frequently used product codes include ART 6, ART 9, ART 15, ART 20, ART 25, TS40, and TS60.

-

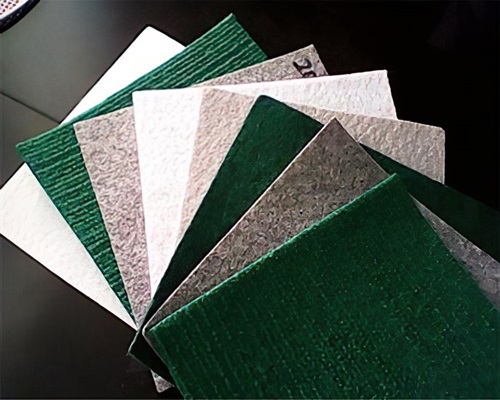

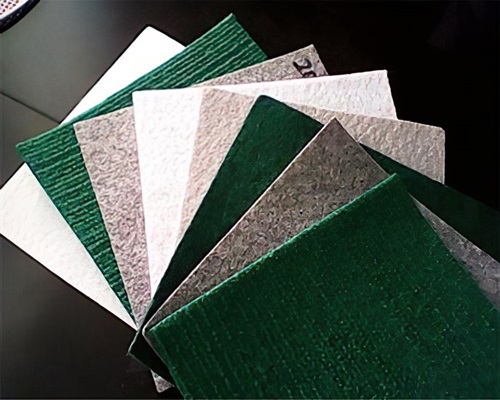

Composite Geotextiles: Combine woven and non-woven geotextiles, offering superior strength and load-bearing capacity. They are often used in projects demanding high technical strength and load resistance.

Functions of Geotextiles:

-

Separation: Prevent the intermixing of different material layers, such as soil and gravel in roadbeds, maintaining the structure and stability of construction materials.

-

Filtration and Drainage: Allow water to flow through while retaining soil, sand, and gravel particles, facilitating efficient drainage and preventing erosion.

-

Protection: Shield underlying material layers from environmental factors like water, acids, and alkalis, extending the lifespan of the construction project.

-

Reinforcement: Provide horizontal shear resistance to enhance slope stability.

-

Ground Stabilization: Facilitate the first construction layer, reducing its thickness, ensuring easy movement of construction equipment, increasing load-bearing capacity and uniform deformation, resisting localized damage zones, and enhancing reinforcement.

Applications of Geotextiles:

-

Transportation Projects: Increase the stability and durability of structures built on weak ground, such as soft clay and mud.

-

Hydraulic Engineering and Embankments: Serve as a surface cover with geotextile tubes (or bags) filled with sand to reduce the hydraulic impact of water flow on the shore. Additionally, they can replace reverse filter layers to lower the groundwater level and ensure that the foundation material is not washed away by the seepage flow.

-

Construction Projects: Reinforce weak ground, such as in vertical drains and foundation applications.

Where to Buy Geotextiles:

Geotextiles are crucial materials in construction projects. Selecting and using the appropriate type of geotextile will enhance the project’s quality, ensure safety, and save costs. GABICO, with over 20 years of experience, specializes in supplying geotextiles for construction projects nationwide.

Benefits of Choosing GABICO :

- Superior product quality at the most competitive prices.

- Prompt delivery time, with customers able to inspect product quality at the manufacturing site.

- GABICO gabions are manufactured on modern production lines with a strong and highly skilled workforce, meeting most project acceptance progress requirements.

- Production according to drawings and orders.

- Diverse product range with accompanying accessories.

- Flexible payment methods, providing multiple proactive payment options for buyers.